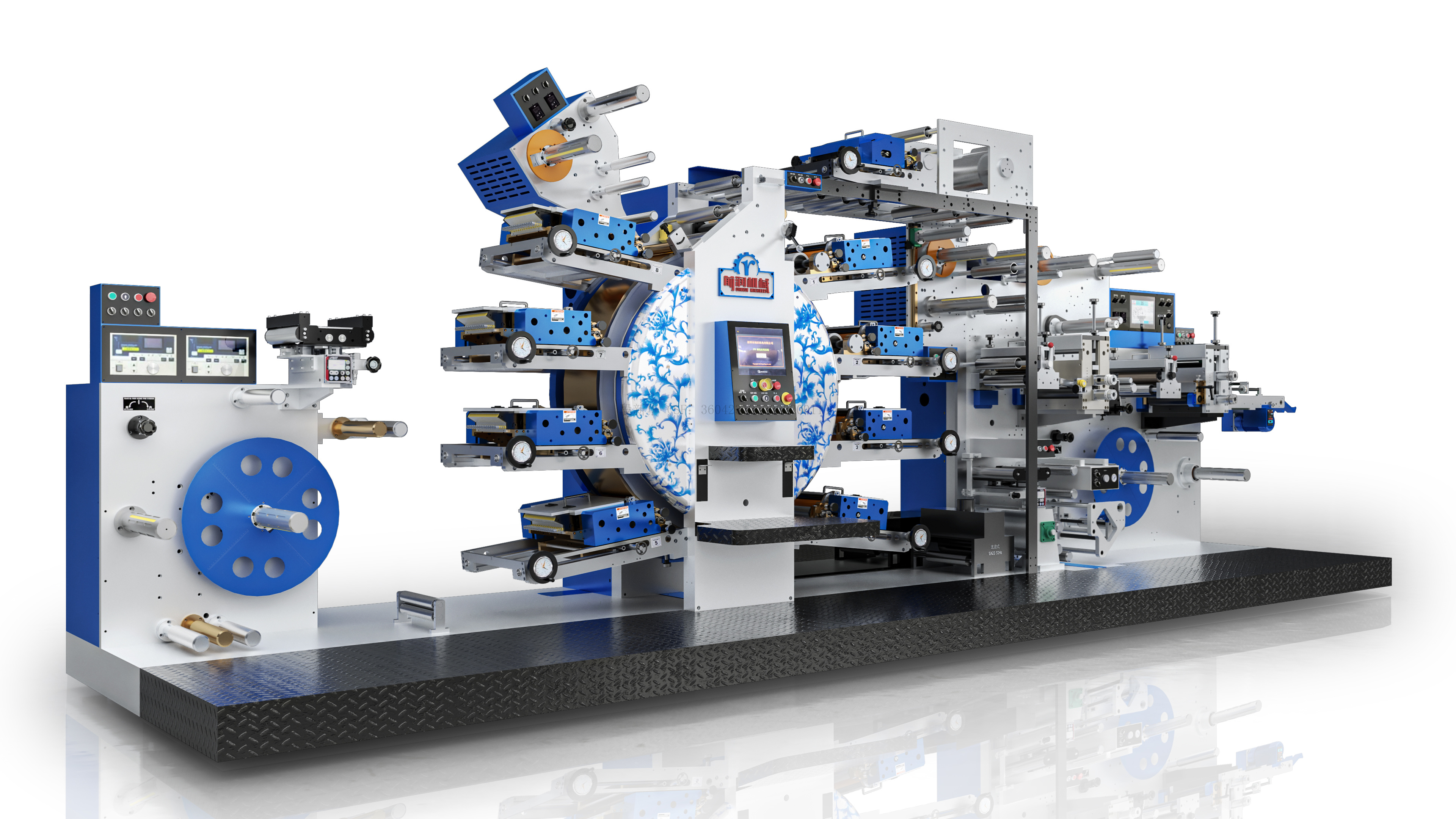

RS series CI full rotary printing machine,CI rotary printing machine for film packaging

RS260/340/460 satellite letterpress rotary printing press is a servo modular industrial design independently developed by Qianrun, which is unique in the industry. It is a multi-process combined full rotary printing press.

Category:

Keyword:

Cl rotary Letterpress Printing Machine

printing

rotary

letterpress

CI rotary printing machine for film packaging

Description

RS260/340/460 satellite letterpress rotary printing press is a servo modular industrial design independently developed by Qianrun, which is unique in the industry. It is a multi-process combined full rotary printing press. The intelligent servo gap round die-cutting system (magnetic roller replacement-free) can save the cost of replacing magnetic rollers, improve the efficiency of tool change, and realize the combination of gap and full rotary system die-cutting. The machine integrates special configurations such as hot stamping, letterpress, flexographic printing, and circular knife, which is suitable for label processing in various industries and can achieve multi-functional label printing effects.

In the world of film packaging, the CI rotary printing machine for film packaging has emerged as a game - changer.The CI rotary printing machine for film packaging is a highly sophisticated piece of equipment. It is specifically engineered to meet the demanding requirements of printing on film materials, which are widely used in various packaging applications, from food packaging to consumer goods packaging.

One of the most remarkable features of this machine is its precision. With a central impression cylinder design, it ensures accurate and consistent printing across the entire width of the film. This precision is crucial for creating high - quality packaging prints, as it allows for sharp images, clear text, and vibrant colors. Whether it's printing brand logos, product information, or eye - catching graphics, the CI rotary printing machine delivers outstanding results.

The machine also offers high - speed printing capabilities. In today's fast - paced manufacturing environment, speed is of the essence. This printing machine can operate at impressive speeds, significantly increasing the production efficiency of film packaging. Manufacturers can meet tight deadlines and large volume orders without sacrificing print quality.

Another advantage lies in its versatility. It can handle a wide range of film types, including polyethylene, polypropylene, and other commonly used packaging films. This flexibility makes it suitable for different packaging needs and allows manufacturers to diversify their product offerings.

In terms of environmental considerations, modern CI rotary printing machine for film packaging are designed to be more energy - efficient. They consume less power compared to older printing technologies, which not only reduces operational costs but also has a positive impact on the environment. Additionally, some machines are equipped with advanced ink systems that use eco - friendly inks, further minimizing the environmental footprint.

The technology behind these machines is constantly evolving. Manufacturers are investing in research and development to improve the performance of CI rotary printing machines. For example, the integration of digital control systems allows for more precise adjustment of printing parameters, such as pressure, speed, and ink distribution. This results in even better print quality and fewer rejects.

Moreover, the user friendly interface of these machines makes them accessible to operators with different levels of experience. Training requirements are minimized, and operators can quickly learn to operate and maintain the machine, ensuring smooth production processes.

The CI rotary printing machine for film packaging is indeed a vital asset for the packaging industry. It combines precision, speed, versatility, and environmental - friendliness, making it an ideal choice for companies looking to enhance their film packaging printing capabilities and stay competitive in the market.

| Type | RS260/340/460 |

| Print color | 2-12colors |

| Print web width | 260/340/460mm |

| Printing repeat length | 190.5mm(7.5")-457.2mm(18") |

| (Max rewind/unwind roll dia) | Ф800mm |

| Max mechanical speed | 100m/min |

| Power(V/Kw) | 380V,3phase,45KVA,50/60HZ |

Advantage

We are willing to work together with you to establish a long-term win-win mechanism and share the joy of success!

Product Consultation

If you have found your desired products or want to design your exclusive products, please feel free to contact, we are here for you 24/7.